Foam density measures how much material is packed into a specific volume, usually in pounds per cubic foot or kilograms per cubic meter. The higher the density, the more durable and supportive the foam tends to be, making it suitable for heavy-duty or long-lasting uses. Lower densities are lighter and softer but less durable. Understanding foam density helps you choose the right material for your needs, and there’s more to uncover about how it impacts performance.

What Is Foam Density and How Is It Measured?

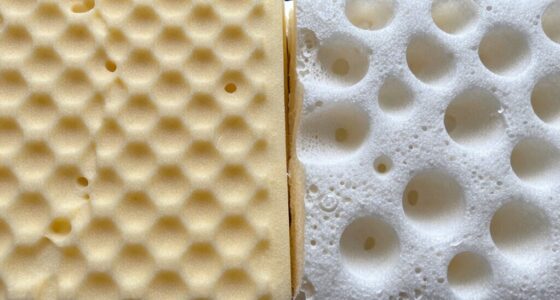

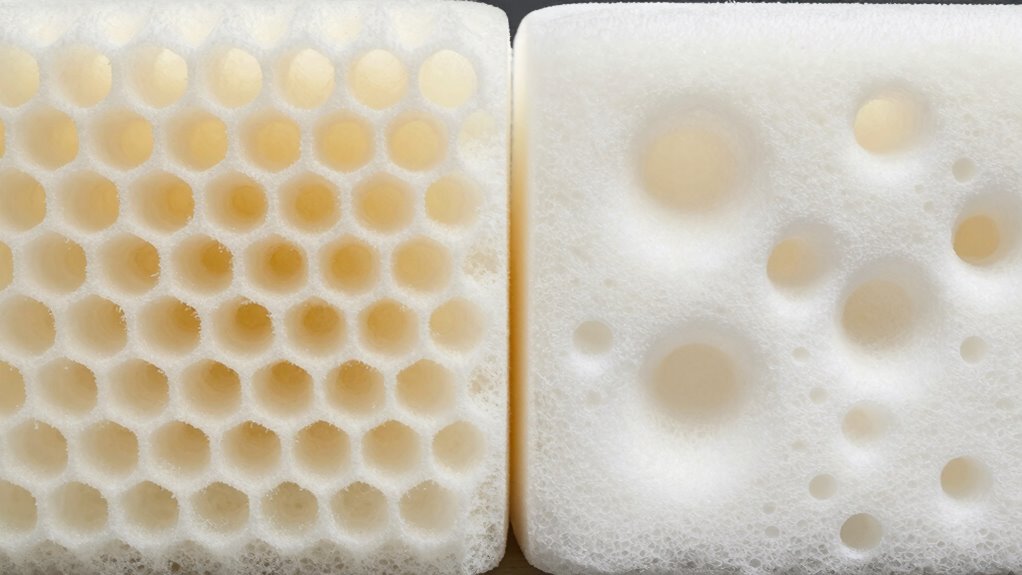

Have you ever wondered what determines a foam’s quality and performance? Foam density primarily depends on its chemical composition and manufacturing process. The chemical composition includes the types and amounts of raw materials used, such as polyols and isocyanates, which influence the foam’s structure. The manufacturing process, involving mixing, curing, and molding, affects how tightly the cells are packed together. Density is measured by dividing the foam’s weight by its volume, typically expressed in pounds per cubic foot (lb/ft³) or kilograms per cubic meter (kg/m³). Higher-density foams contain more material per unit volume, making them generally more durable and supportive. Understanding these aspects helps you assess foam quality, as both composition and production methods directly impact the foam’s performance. Additionally, sound healing science offers insights into how underlying vibrations might influence material properties in innovative ways, enhancing the potential for innovative material design. Recognizing the significance of material density can lead to better choices in applications requiring durability and resilience, especially when considering the manufacturing process that influences the final product. Furthermore, awareness of material consistency can assist in predicting how foam will perform over time under various conditions.

Why Does Foam Density Matter for Durability and Comfort?

Foam density directly influences how well a cushion or mattress holds up over time and how comfortable it feels during use. Higher density foam typically has a more robust foam structure, making it more durable and less prone to sagging or breakdown. The material composition of dense foam includes tightly packed cells, which enhance support and longevity. Additionally, foam structure plays a crucial role in determining both comfort and durability. When foam density is optimized, your cushion or mattress provides consistent support and remains comfortable longer, ensuring better value and a more satisfying experience over time. Understanding foam density and how it interacts with other factors helps you select products that balance comfort with durability. Moreover, European cloud innovation promotes the development of advanced materials that can further improve foam performance and sustainability. Incorporating industry standards ensures that foam products meet quality and safety benchmarks for consumers. Recognizing the importance of odor and scent can also help in selecting products that are free from unpleasant smells, contributing to a healthier environment.

What Are Typical Foam Density Ranges and Their Uses?

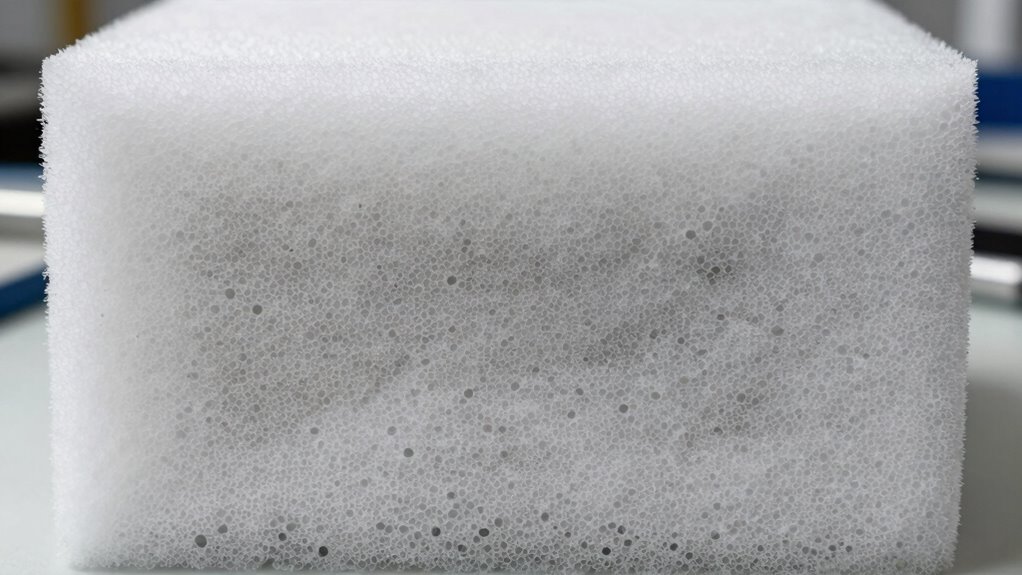

Understanding typical foam density ranges is essential for choosing the right material for your needs. Foam densities usually fall between 1 and 2 pounds per cubic foot (lb/ft³) for general use. Lower densities, around 1 lb/ft³, are lightweight and flexible, making them suitable for packaging materials or cushioning delicate items. Medium densities, about 1.5 to 2 lb/ft³, often support mattress support, providing a balance of comfort and durability. Higher densities, exceeding 2 lb/ft³, are more durable and resilient, ideal for heavy-duty applications or high-traffic seating. Knowing these ranges helps you select foam that aligns with your specific needs, whether it’s for cushioning packaging, providing reliable mattress support, or creating long-lasting furniture. Additionally, choosing the appropriate foam density can influence the longevity and performance of your upholstered pieces or packaging solutions. Understanding foam density can also help predict how well the material will perform over time under repeated use, especially when considering durability standards. Recognizing how material properties impact foam performance is crucial for making informed decisions about your foam choices.

How Can You Interpret Foam Density Labels and Specs?

Interpreting foam density labels and specs can seem tricky at first, but understanding what the numbers mean makes choosing the right material easier. Foam classification systems, such as the foam density ranges, follow specific labeling standards that help you compare materials accurately. Typically, these labels list the density in pounds per cubic foot (pcf) or kilograms per cubic meter (kg/m³). Higher numbers indicate denser, more durable foam, while lower numbers suggest softer, lighter options. Always check the labeling standards used by manufacturers to assure consistency. This way, you can confidently evaluate foam options based on their density specs, aligning them with your project’s durability and comfort needs. Recognizing piercing aftercare and how it impacts material choice can also provide insight into the design and durability of certain foam styles. Clear interpretation of these labels helps you select the best foam for your application.

How Do You Choose the Best Foam Density for Your Project?

Choosing the right foam density depends on your specific project requirements and how you’ll use the material. To make the best choice, consider the foam’s composition and how it’s manufactured, as these factors influence durability and performance. Higher-density foams generally offer better support and longevity, ideal for furniture or bedding, while lower densities provide softer comfort for cushions or insulation. Understanding the manufacturing processes can reveal how the foam’s density was achieved and its potential effects on quality. Manufacturing techniques can significantly affect the foam’s overall durability and consistency. Think about the stress the foam will face and select a density that balances comfort with durability. Additionally, foam composition plays a crucial role in determining the final properties of the material, impacting its resilience and suitability for your application. Recognizing the material properties can help predict how the foam will behave over time under various conditions. Incorporating knowledge of material testing can further ensure you select a foam that meets your specific durability needs. Being aware of industry standards and testing methods can also guide you toward choosing a product that adheres to quality benchmarks. By evaluating your project’s needs and the foam’s composition and manufacturing details, you can confidently choose a foam density that guarantees superior performance and longevity.

Frequently Asked Questions

How Does Foam Density Impact Fire Safety Standards?

Foam density plays a crucial role in fire safety because higher-density foam generally offers better fire resistance and slows down the spread of flames. You’ll find that dense foam performs better in meeting fire safety standards, reducing risks during fires. It also enhances foam performance by providing stability and durability under heat, ensuring the material maintains its integrity longer, which is essential for protecting occupants and property.

Can Foam Density Change Over Time or With Use?

Yes, foam density can alter over time because of aging effects and usage variability. As you use foam, it may settle, break down, or become compressed, leading to a decrease in density. Environmental factors like heat, moisture, or repeated loading accelerate this process. Over time, these changes can affect the foam’s durability and performance, so regularly checking and replacing foam ensures it maintains its protective qualities.

Is Higher Foam Density Always Better for All Applications?

Higher foam density isn’t always better; it depends on your application. While increased density offers durability and support, it also results in heavier, less flexible foam, which can be a drawback for comfort or ease of use. You should consider the density trade-offs and match the foam’s properties to your specific needs. For instance, high-density foam suits heavy-duty cushions, but lower density may be better for softer, more flexible applications.

How Does Foam Density Affect Environmental Sustainability?

You might find that higher foam density impacts environmental sustainability more than you expect. Denser foams often contain more chemicals, which can hinder recyclability considerations and biodegradability factors. This coincidence means choosing lower-density foams might be better for eco-friendliness, as they typically break down faster and are easier to recycle. So, when prioritizing sustainability, consider foam density as a key factor influencing the overall environmental footprint of your materials.

Are There Industry Certifications Related to Foam Density?

Yes, there are industry certifications related to foam density. Certification standards like CertiPUR-US and GREENGUARD assess foam quality, safety, and environmental impact, including density levels. Industry recognition of these certifications confirms you that the foam meets rigorous benchmarks for durability and safety. When choosing foam, look for these labels to guarantee you’re getting a product that aligns with trusted standards, supporting both quality and sustainability in your purchase.

Conclusion

Now that you understand foam density, picture it as the heartbeat of your project—steady, reliable, and essential. As you select the right foam, imagine it cradling comfort or standing strong against wear. Let the numbers guide you like a compass through the sea of options. Trust your instincts, weigh the specs, and feel confident knowing you’re choosing durability and comfort woven into every fiber. Your perfect foam match is just a decision away.