ILD stands for Indentation Load Deflection and measures how firm or soft foam feels under pressure. A lower ILD means the foam is softer and compresses easily, offering plush support, while a higher ILD indicates firmer foam that resists compressing, providing more support and stability. Knowing what ILD ratings mean helps you pick the right foam for comfort or structure. Keep exploring to learn how to select the best foam for your needs.

What Is ILD and Why Does It Matter?

What exactly is ILD, and why should you care? ILD, or Indentation Load Deflection, measures how firm or soft foam feels under pressure. It’s a key indicator of foam density, which directly influences comfort and durability. Manufacturers rely on strict manufacturing standards to guarantee ILD ratings are consistent, so you know what you’re getting. Higher ILD numbers mean firmer foam, while lower ones indicate softer material. Understanding ILD helps you select the right foam for your needs, whether for a mattress, cushion, or furniture. It also ensures the foam will perform as expected over time. By paying attention to ILD, you’re making informed choices that impact comfort, longevity, and overall satisfaction with your foam products. Additionally, knowing about foam testing standards helps you understand how these ratings are verified and maintained. Recognizing the importance of foam quality control can further assure you of the product’s reliability and performance. When selecting foam, considering the manufacturing process can also provide insights into its consistency and quality assurance. Being aware of industry standards further supports making confident, well-informed decisions. Moreover, understanding material properties can help you better evaluate the suitability of foam for specific applications.

How Does ILD Measure Foam Firmness?

Have you ever wondered how foam firmness is actually measured? It all comes down to ILD, which uses a standardized method involving pressure mapping. First, a sample of foam is placed under a testing device that applies a specific amount of pressure. The device measures how much force it takes to compress the foam to a designated height. This process considers foam density, as denser foam generally requires more pressure to compress. Pressure mapping sensors record the force distribution across the foam surface, ensuring consistent measurements. The resulting data indicates the foam’s firmness level, with higher ILD values representing firmer foam. This precise measurement helps you understand the firmness you’re choosing, ensuring comfort and support tailored to your needs.

What Are Typical ILD Ranges and Uses?

Understanding typical ILD ranges helps you choose the right foam for your needs. You’ll find that different applications require specific firmness levels, from soft to firm. Knowing how to select the appropriate ILD guarantees ideal comfort and support for your project. Additionally, considering the type of storytelling involved can enhance your overall selection process. For example, some foams are better suited for customized comfort that aligns with personal preferences or specific product demands. Recognizing the benefits of proper firmness ensures you achieve the desired balance between support and softness for optimal results. Moreover, understanding market standards and classifications can aid in making more informed decisions when selecting foam types. Being aware of the industry benchmarks helps ensure you select products that meet quality and safety standards.

Typical ILD Ranges

Typical ILD ranges can vary depending on the specific application and measurement method, but generally, they fall within certain established limits. These ranges help you understand foam softness and firmness for different uses. For example, softer foams used in cushions have lower ILD values, while firmer foams for support have higher ILD values. The foam density and manufacturing process influence these ranges. Here’s a quick look:

| ILD Range | Typical Use |

|---|---|

| 2-5 | Soft, comfort-focused foam |

| 6-12 | Medium softness, general use |

| 13-20 | Firm, supportive foam |

| 21-30 | Very firm, high support |

| 31+ | Extra firm, specialty use |

Knowing these ranges helps you select foam that fits your needs perfectly. Additionally, understanding color accuracy can be important when evaluating visual qualities in projectors. The ILD measurement also plays a role in backyard transformation projects where comfort is key, such as creating cozy seating areas with foam cushions. Furthermore, measurement techniques can influence how ILD values are interpreted, ensuring you choose the right foam for your specific application.

Common Foam Applications

Knowing the ILD ranges helps you choose the right foam for various applications. Softer foams with lower ILDs, typically between 8-20, are ideal for cushions that require comfort and conforming support, like seat pads and upholstery. Medium ILD foams, around 20-40, are common in mattress toppers and ergonomic cushions, offering a balance between softness and support. Firm foams with ILDs above 40 are used in structural elements or support layers where durability and firmness are essential. Foam density also plays a role, affecting weight, durability, and cushion design. Higher-density foams are often paired with firmer ILDs for long-lasting furniture, while lower-density foams provide a softer feel. Understanding foam properties is crucial for selecting the appropriate ILD for your specific needs, ensuring comfort and longevity. Additionally, foam composition impacts how the foam responds over time, influencing its suitability for different environments. Understanding foam density and composition can help you make more informed choices for your projects. Recognizing the importance of foam durability can help you select materials that stand up to regular use and environmental factors. Understanding these typical ILD ranges helps you match foam to your specific needs, ensuring comfort and longevity. Choosing the right foam level is essential for achieving the desired balance of comfort and support in your application.

Selecting Appropriate ILD

When selecting the right ILD for your application, it’s important to contemplate the specific needs for comfort, support, and durability. Typical ILD ranges vary from soft (around 10-20) for plush comfort to firm (above 40) for more support. Foam density and material composition influence ILD; higher-density foams tend to be firmer, providing greater support, while lower-density foams offer softer feel. Understanding these ranges helps you match the foam to its purpose, whether for bedding, cushions, or medical use. Consider the following when choosing ILD:

- Soft foams (ILD 10-20) for comfort and plushness

- Medium firmness (ILD 20-30) for general support

- Firm foams (ILD 30-40) for structure and durability

- Very firm (above 40) for specialized applications

ILD testing methods are essential to accurately determine foam firmness and ensure proper selection. Additionally, knowing the standardized measurement techniques can help you compare different foam products reliably. Moreover, implementing connected fitness technology can assist in monitoring and optimizing your foam choices for ergonomic support in your home gym or wellness space. Incorporating foam material properties understanding can further enhance your ability to select the most suitable foam for your needs.

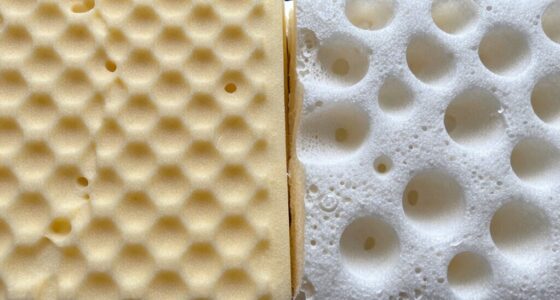

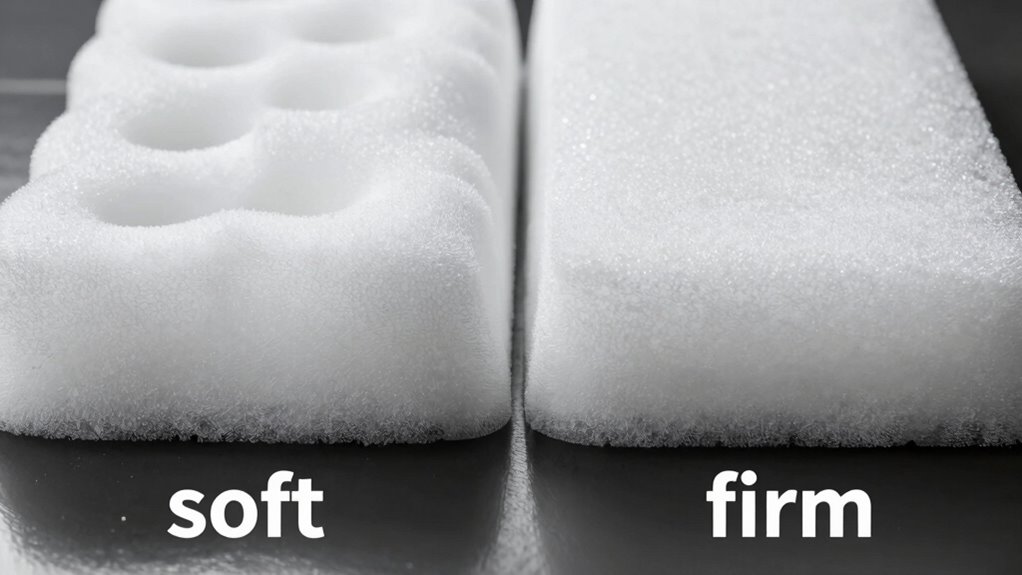

How Do ILD Ratings Differ for Soft and Firm Foam?

Have you ever wondered how ILD ratings vary between soft and firm foam? Typically, soft foam has lower ILD values, indicating it requires less force to compress, which contributes to a plush, cushioned feel. Firm foam, on the other hand, has higher ILD ratings, meaning it needs more pressure to compress, offering more support and durability. Foam density also plays a role, as higher-density foams tend to have higher ILD ratings, regardless of softness or firmness, affecting overall comfort. When conducting a comfort assessment, understanding these differences helps you select the right foam for your needs. Soft foam with low ILD provides a gentle, cozy feel, while firm foam with higher ILD offers stability and support. Recognizing these distinctions ensures better mattress and cushion choices. Understanding ILD ratings is essential for making informed decisions about foam comfort and support levels. Additionally, factors like foam composition influence how ILD ratings translate into real-world comfort.

Why Do Different Applications Need Different ILD Levels?

Different applications require different ILD levels because comfort needs vary based on usage. You need the right balance of support and pressure relief to prevent discomfort or injury. Additionally, durability and longevity are key factors that influence the ideal ILD for each specific purpose. For example, selecting the appropriate dog bed size and support ensures comfort for your Golden Retriever or Rottweiler supports healthy joints.

Application-Specific Comfort Needs

Ever wondered why certain applications require specific ILD levels? It’s because different uses have unique comfort needs. For example, memory foam in mattresses benefits from a softer ILD to contour to your body, providing pressure relief. Ergonomic seating demands a firmer ILD to support proper posture and reduce strain. The goal is to match the foam’s firmness with the application’s purpose. Softer foams offer plush comfort, ideal for relaxation, while firmer foams provide stability for active or prolonged use. Understanding these needs helps you select the right ILD for comfort and performance.

- Memory foam for mattresses favors softer ILD for contouring

- Ergonomic chairs require firmer ILD for support

- Softer foam enhances plushness and pressure relief

- Firmer foam ensures stability during extended use

Support and Pressure Relief

Choosing the right ILD level directly impacts how well a foam supports your body and alleviates pressure points. Higher ILD foams tend to have greater foam density, providing firmer support ideal for applications requiring spinal alignment or heavier weight distribution. Lower ILD foams are softer, offering more comfort and pressure relief for sensitive areas like joints or for those seeking plush cushioning. Your comfort levels depend on matching the foam’s firmness to your specific needs. If support is your priority, a firmer foam with a higher ILD will prevent sinking too deep and maintain stability. Conversely, for pressure relief and a more cushioned feel, a softer foam with a lower ILD will evenly distribute weight and reduce discomfort. Selecting the right ILD ensures suitable support and comfort tailored to your application.

Durability and Longevity

Have you ever wondered why some foam cushions last longer than others? The answer often lies in foam density and the manufacturing process. Higher-density foam generally offers better durability because it withstands wear and tear over time. The manufacturing process also impacts longevity, as quality control guarantees consistent cell structure and material strength. Softer foams with lower ILD may feel plush initially but tend to break down faster. Conversely, firmer foams with higher ILD maintain their shape longer, making them ideal for heavy or prolonged use. Choosing the right ILD for your application depends on balancing comfort with durability.

- Foam density determines how long the foam holds up

- Manufacturing quality affects overall lifespan

- Softer foams wear out quicker

- Firmer foams last longer and retain shape

What Are the Limits of Using ILD Alone?

While ILD can provide valuable insights into foam firmness, relying on it alone has notable limitations. ILD measures how much force is needed to compress foam, but it doesn’t account for foam durability over time or how well the foam maintains its properties with repeated use. Foam durability impacts longevity, so a foam with a good ILD might still wear out quickly if it’s not durable enough. Additionally, ILD doesn’t reveal foam recyclability or environmental impact, which are increasingly important factors. Using ILD alone can lead to selecting foam that feels ideal initially but may not perform well long-term or be eco-friendly. To make the best choice, consider ILD alongside other factors like durability and recyclability.

How to Choose the Right ILD for Your Needs?

Selecting the right ILD depends on understanding your specific comfort and support needs. Your choice should consider how foam composition and manufacturing processes influence firmness and feel. Softer foams, often made with different materials or manufacturing techniques, provide more cushioning, ideal for pressure relief. Firmer foams, created through specific manufacturing methods, offer more support for heavier or more active individuals. To choose the best ILD, consider:

- Your sleeping position and body weight

- The density and material of the foam

- The desired level of pressure relief or support

- How foam’s manufacturing process impacts firmness and durability

Tips for Interpreting ILD When Shopping

Interpreting ILD ratings can seem confusing at first, but understanding what the numbers mean helps you make smarter choices. When shopping for foam, consider the foam density alongside ILD to gauge durability and support. Higher foam density generally indicates a longer-lasting material, while ILD measures the foam’s firmness or softness. Comfort grading is a helpful way to compare different foams quickly—softer foams usually have lower ILD values, and firmer ones have higher values. Look at the combination of foam density and ILD to match your comfort preferences and needs. Don’t forget to check product descriptions for clarity on these ratings, so you can select foam that offers the right balance of softness or firmness for your comfort.

Frequently Asked Questions

How Does Temperature Affect Foam ILD Measurements?

Temperature affects foam ILD measurements because foam temperature influences its firmness and resilience. When foam is colder, it tends to be firmer, which can lead to higher ILD readings, while warmer foam becomes softer, reducing ILD accuracy. To guarantee precise ILD measurements, you should measure foam at a consistent temperature, ideally room temperature, because fluctuations in foam temperature can skew results and compromise ILD accuracy.

Can ILD Change Over Time With Foam Use?

Think of foam like a trusty pair of shoes. Over time, foam aging and usage effects can cause ILD to change, making your mattress feel softer or firmer. As you use it, the foam compresses and loses some of its original resilience. So, yes, ILD can fluctuate over time, reflecting how the foam adapts to your body and habits, ultimately affecting your sleep comfort.

Are There Industry Standards for ILD Testing Procedures?

Yes, there are industry standards for ILD testing procedures. You’ll find that foam compression testing protocols are standardized by organizations like ASTM and ISO, ensuring consistency across products. These protocols specify how to measure ILD accurately, including test conditions and equipment. Following these standards helps you compare foam firmness reliably, making sure the foam’s softness or firmness meets quality expectations and provides the comfort or support desired.

How Does Foam Density Relate to ILD Ratings?

Foam density directly influences ILD ratings because higher density foam generally requires more compression force, resulting in higher ILD values. When you test foam compression, you’ll notice that density variability can cause differences in ILD readings, even within the same foam batch. Understanding this relationship helps you select the right foam for comfort and durability, ensuring consistent performance regardless of slight density variations.

Is ILD Consistent Across Different Foam Manufacturers?

Think of ILD like a fingerprint—unique, yet sometimes similar across different manufacturers. ILD isn’t entirely consistent because manufacturing consistency and foam formulation vary. While two brands might claim the same ILD, differences in raw materials and production processes can affect the feel. So, you should test or compare samples, rather than assume ILD ratings are directly interchangeable, since foam formulation impacts the firmness you experience.

Conclusion

Understanding ILD helps you choose foam that truly fits your needs. But remember, numbers aren’t everything—your comfort depends on more than just firmness ratings. As you explore options, consider how different ILD levels can transform your experience in ways you might not expect. The right choice might surprise you, and the true secret lies in knowing how to interpret and apply what you’ve learned. Are you ready to discover what’s really possible with the right foam?