Phase change materials (PCMs) are substances that absorb and release heat as they melt and solidify, helping keep temperatures steady. When they absorb heat, they change from solid to liquid without getting hotter, and when they release heat, they turn back into solid, warming the surroundings. This ability to store and release energy makes PCMs useful for energy savings and temperature control in daily life. If you want to learn more about how they work and their benefits, keep going.

What Are Phase Change Materials (PCMs)?

Phase change materials, or PCMs, are substances that absorb and release thermal energy during their melting and solidifying processes. They play a vital role in thermal regulation, helping maintain stable temperatures by storing excess heat or releasing it when needed. This unique ability makes PCMs a key focus of material innovation, as engineers develop new substances to improve energy efficiency. When temperatures rise, PCMs melt, absorbing heat without a temperature increase, and as they cool, they solidify, releasing stored energy. This cycle allows for effective temperature control in various applications. By integrating PCMs into building materials or cooling systems, you can optimize energy use and reduce reliance on traditional heating or cooling methods. Their ability to adapt to temperature changes makes them a valuable tool in sustainable design. Additionally, the thermal properties of PCMs can be tailored to specific climate conditions, enhancing their versatility and effectiveness. As research advances, new formulations of PCMs are being designed to further improve their energy storage capacity and environmental sustainability.

How Do PCMs Work? Simplified Explanation

When a PCM reaches its melting point, it absorbs heat and changes from solid to liquid, storing energy in the process. During freezing, it releases that stored energy as it solidifies back to its original form. This cycle of melting and freezing helps PCMs regulate temperature by absorbing or releasing heat as needed. Additionally, modern kitchen technology increasingly utilizes PCMs in smart appliances to enhance energy efficiency and maintain optimal temperatures. In fact, the integration of thermal energy storage in these devices allows for more sustainable and cost-effective heating and cooling solutions. Proper maintenance practices are essential to ensure PCMs operate effectively over time, especially as they are incorporated into various recovery devices like massage guns to help manage temperature-sensitive components effectively. Incorporating smart home integration can further optimize the performance of PCM-based systems within a connected environment.

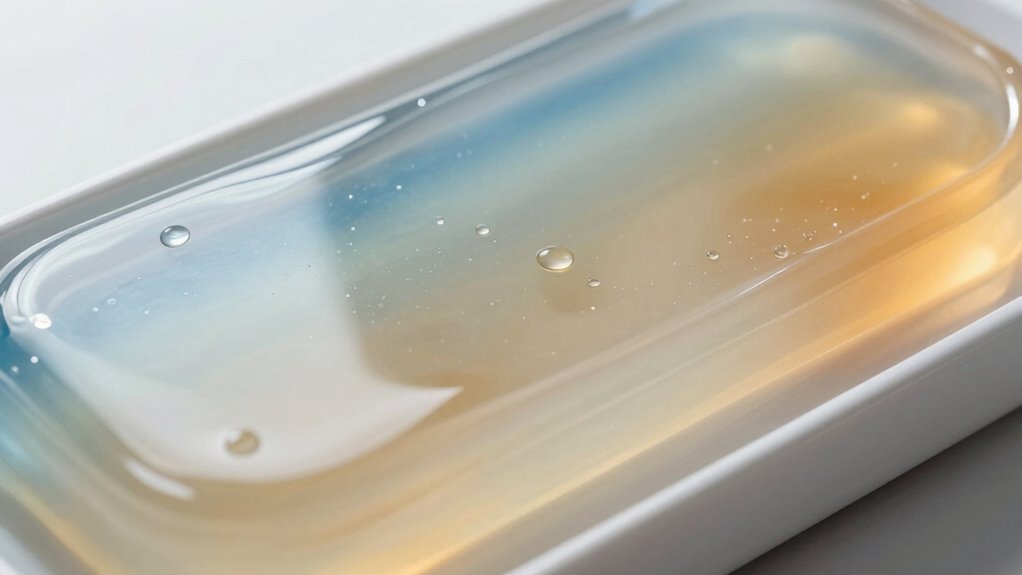

Melting and Freezing Process

As a substance reaches its melting point, it absorbs heat without increasing in temperature, allowing it to change from solid to liquid smoothly. This process is called a phase change, specifically melting, which involves a thermal shift from solid to liquid. During melting, your PCM undergoes this thermal transition, where energy is used to break the structured bonds holding the solid together. Conversely, during freezing, the liquid releases heat and transitions back to a solid. In both cases, the temperature stays constant until the entire phase change completes. This ability to absorb or release heat during the phase change makes PCMs effective for thermal regulation. The melting and freezing processes enable the material to store or release thermal energy efficiently, helping maintain stable temperatures. Additionally, this thermal energy storage capability allows PCMs to be used in energy-saving systems, making them an important component in smart thermal management. Understanding these processes highlights how PCMs contribute to energy efficiency and sustainable design solutions.

Energy Absorption and Release

Have you ever wondered how PCMs help regulate temperature? It’s all about energy absorption and release. When the environment heats up, PCMs absorb heat, storing it as latent heat during melting. As temperatures drop, they release that stored heat, cooling the surroundings. This cycle provides effective thermal storage, making heat regulation smooth and consistent. To visualize this, consider the table below:

| Temperature | PCM State | Energy Movement |

|---|---|---|

| Low | Solid | Releases heat to environment |

| Melting Point | Melting (liquid) | Absorbs heat |

| High | Liquid | Stores heat |

| Freezing Point | Freezing (solid) | Releases heat |

| Cooler | Solid | Maintains temperature |

Additionally, understanding the phase change process enhances our appreciation of how PCMs contribute to energy efficiency and comfort. This process keeps your space comfortable by balancing heat flow efficiently. Understanding thermal regulation helps explain how PCMs contribute to energy efficiency and comfort. Recognizing the energy absorption and release cycle reveals how PCMs can be tailored for specific temperature ranges, making them versatile for various applications. Moreover, the ability of PCMs to adapt to different environments underscores their usefulness in diverse settings. Furthermore, the material properties of PCMs influence their effectiveness in different applications, highlighting the importance of selecting the right type for specific needs.

What Are the Different Types of PCMs?

There are various types of PCMs, classified by their physical state—solid, liquid, or gel. You’ll also find different PCMs tailored for specific applications, like thermal regulation in building materials or electronics cooling. Understanding these distinctions helps you choose the right PCM for your needs. Additionally, selecting the appropriate type depends on factors such as melting point and heat capacity, which are essential for effective thermal management material properties. Recognizing the thermal properties of each PCM type ensures optimal performance in your particular application. Some PCMs are engineered to have specific phase change temperatures, making them suitable for diverse environments and uses. These properties are carefully engineered to meet precise performance criteria for various industries and functions. Properly matching the PCM’s melting point with the intended temperature range is crucial for maximizing efficiency and safety.

Types by State

What are the different types of phase change materials (PCMs) based on their physical state? PCMs are mainly classified into solid-liquid, solid-solid, and liquid-gas types. Solid-liquid PCMs are the most common; they absorb or release heat during melting and solidifying. They typically have high thermal conductivity, allowing efficient heat transfer, and good chemical stability, which helps them last through many cycles without degrading. chemical stability is a key factor in their longevity. Solid-solid PCMs change their crystal structure without melting, offering advantages like minimal volume change. These materials are especially useful in applications where containment is an issue. thermal conductivity influences how quickly they can absorb or release heat, impacting their efficiency. Liquid-gas PCMs are less common and involve phase changes at very high temperatures, often used in specialized applications. The physical state impacts how the material stores and releases energy, influencing its suitability for specific uses. Additionally, the horsepower of electric dirt bikes can be a factor in their performance, especially for off-road applications.

Types by Application

Different types of PCMs are chosen based on their specific applications to optimize energy storage and thermal regulation. Depending on your needs, the material composition varies for different uses. Here are some common types:

- Building materials – These PCMs help regulate indoor temperature by absorbing or releasing heat, improving thermal regulation in walls and ceilings.

- Textiles – Incorporated into clothing, they maintain comfort by managing body temperature through phase change.

- Electronics – Used to prevent overheating, these PCMs absorb excess heat during operation, safeguarding sensitive components.

- Packaging – Designed for temperature-sensitive goods, they keep products cool during transport via their specific material composition.

Choosing the right type depends on your application’s thermal regulation needs and the PCM’s material makeup.

How Are PCMs Used in Daily Life?

Ever wondered how phase change materials (PCMs) make everyday life more comfortable and efficient? They’re commonly used in products that promote thermal regulation and maintain temperature stability. For example, in clothing, PCMs absorb excess heat when you’re hot and release it when you’re cold, helping you stay comfortable without bulky layers. In building materials, PCM-infused drywall or insulation helps regulate indoor temperatures, reducing energy consumption. You might also find PCMs in packaging for temperature-sensitive items like medicines or food, keeping them cool during transit. Additionally, in bedding, PCM-infused mattresses or pillow inserts help maintain a consistent, comfortable temperature throughout the night. These practical applications make your daily routines more convenient by subtly balancing temperature fluctuations around you.

What Are the Benefits of Using PCMs for Energy Savings?

Using phase change materials (PCMs) can considerably reduce your energy bills by enhancing thermal regulation in buildings. By stabilizing indoor temperatures, PCMs decrease the need for heating and cooling, saving you money. Additionally, they positively impact the environment by lowering energy consumption and reducing greenhouse gas emissions. Here are some key benefits:

Using PCMs reduces energy bills and environmental impact through improved thermal regulation.

- Improved thermal regulation keeps your space comfortable year-round

- Reduced energy costs due to less reliance on HVAC systems

- Lower environmental impact by decreasing carbon footprint

- Extended lifespan of heating and cooling equipment, saving maintenance costs

These benefits make PCMs a smart choice for sustainable living, helping you save money while contributing to environmental preservation.

What Challenges Do PCMs Face? Limitations to Know

While phase change materials offer many benefits, they also face several challenges that can limit their effectiveness. One major issue is cost considerations; high-quality PCMs can be expensive to produce and install, which might deter widespread adoption. Additionally, their environmental impact is a concern, as some PCMs contain chemicals that could pose ecological risks if not properly managed or disposed of. Stability over time is another challenge, since some materials can degrade after repeated phase changes, reducing their efficiency. Compatibility with existing building materials and systems can also be problematic, potentially requiring costly modifications. These limitations mean you need to carefully evaluate the benefits against the potential costs and environmental effects before choosing PCMs for your project.

What’s Next for PCM Technology? Innovations to Watch

Advancements in PCM technology are opening exciting possibilities for overcoming current limitations and expanding their practical applications. Researchers are developing smart materials that adapt to environmental changes, improving thermal regulation. These innovations include:

- Enhanced energy storage capacity for longer-lasting thermal regulation.

- Improved stability and durability for everyday use.

- Integration with smart systems for real-time temperature control.

- Eco-friendly, sustainable PCMs that reduce environmental impact.

These developments make PCMs more versatile, reliable, and efficient, paving the way for smarter buildings, apparel, and electronic devices. As these innovations evolve, you’ll see more seamless integration into daily life, helping to optimize energy use and maintain comfortable environments. The future of PCM technology promises smarter solutions that better meet our thermal regulation needs.

How Can I Choose the Best PCM for My Needs?

Choosing the right PCM for your needs depends on understanding your specific thermal management goals and environment. First, consider the desired phase change temperature to match your application. Next, evaluate the material’s thermal conductivity; higher conductivity allows heat to transfer more efficiently, improving performance. Equally important is material stability—select a PCM that maintains its properties over many cycles without degradation. If your environment involves frequent temperature fluctuations, stability becomes critical. Also, assess compatibility with your system’s materials and conditions. By balancing these factors—phase change temperature, thermal conductivity, and stability—you can select a PCM that effectively manages heat, enhances efficiency, and lasts longer. Making an informed choice guarantees your thermal management solution meets your specific needs reliably.

Frequently Asked Questions

Are Phase Change Materials Safe for Household Use?

Yes, phase change materials are generally safe for household use when you follow proper installation guidelines. They are designed with chemical safety in mind, so they don’t pose significant health risks. Just make sure you handle them carefully during installation, avoid damage to the material, and keep them away from children and pets. Following these precautions guarantees safe and effective use of phase change materials in your home.

How Long Do PCMS Typically Last Before Needing Replacement?

You’ll find that phase change materials typically last between 10 to 20 years, depending on their thermal durability and usage conditions. Imagine a snow-covered mountain gradually melting, yet the core remains resilient—your PCM’s material lifespan hinges on how well it sustains its ability to absorb and release heat. With proper care, you can enjoy its energy-saving benefits for decades before considering replacement, ensuring your home stays comfortable and efficient.

Can PCMS Be Recycled or Reused After Use?

Yes, you can recycle and reuse PCMs after their initial use. The recycling process involves collecting the used materials, cleaning, and reprocessing them into new PCM products. While some PCMs have high reuse potential, others may degrade over time, reducing efficiency. Proper recycling helps extend their lifespan and minimizes waste, making it an eco-friendly choice. Just make certain you follow manufacturer guidelines for maximum reuse and recycling.

Are PCMS Environmentally Friendly and Non-Toxic?

Think of PCMs as the green heroes of thermal regulation. They’re generally eco-friendly, boasting properties that minimize environmental impact. While some PCMs have low toxicity concerns, others may contain chemicals that raise safety questions. Overall, many are designed to be non-toxic, making them safer choices. You should check specific product labels, but in general, PCMs can be both effective and environmentally conscious options for managing temperature.

What Maintenance Is Required for Pcm-Based Systems?

You need to perform minimal maintenance on PCM-based systems to ensure thermal stability and maintain storage capacity. Regularly check for any leaks or signs of degradation, and keep the system clean from dust and debris. Guarantee proper insulation around the PCM to prevent temperature fluctuations. Occasionally, verify that the system’s temperature sensors are functioning correctly. These simple steps help maintain ideal performance and extend the system’s lifespan.

Conclusion

Think of phase change materials as the silent heroes in your energy story, quietly balancing temperature like a skilled juggler. They store and release heat, making your home more comfortable and saving energy along the way. As technology advances, these materials are becoming even more effective and versatile. Embracing PCMs is like adding a reliable, eco-friendly teammate to your daily routine—helping you stay cool when it’s hot and warm when it’s cold, effortlessly.