Open coil springs usually feel softer and more adjustable because their exposed coil design allows for easier modifications and gives a more flexible response. In contrast, closed coil springs are tightly wound and structural, which distributes stress evenly and creates a stiffer feel. The differences in construction impact how each spring responds under load, affecting ride comfort and handling. If you keep exploring, you’ll find out more about why these design choices matter.

Key Takeaways

- Closed coil springs are generally stiffer due to tightly wound, enclosed coils that distribute stress evenly.

- Tighter coil spacing in open springs increases stiffness, making them feel firmer under load.

- Material and coil thickness influence spring stiffness, with thicker wire producing a stiffer spring.

- Open coil springs often have adjustable features, allowing tuning that can affect perceived stiffness.

- The structural design and how the coils are arranged significantly impact the spring’s overall stiffness and feel.

What Are Coil Springs and How Do They Work?

Coil springs are simple yet essential components found in many mechanical systems, including orthodontic appliances. They work by storing and releasing energy to apply consistent force, helping move teeth or adjust structures. Over time, however, coil springs can experience spring fatigue, reducing their effectiveness and risking failure. Spring fatigue occurs when repeated compression weakens the metal, making the spring less responsive. Additionally, coil spring corrosion can develop if the spring is exposed to moisture or harsh environments, leading to rust and deterioration. Proper maintenance and material choice can help prevent these issues. Understanding how coil springs function and their vulnerabilities ensures you select the right type for your needs and maintain their performance over time. Material selection plays a crucial role in enhancing spring durability and resistance to environmental damage.

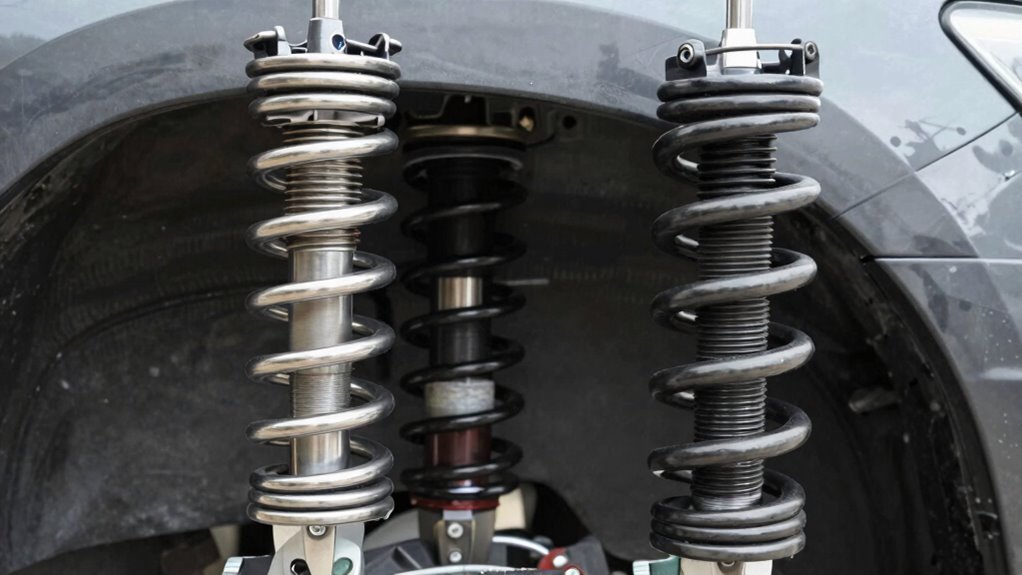

How Do Open Coil Springs Differ From Closed Coil Springs?

Have you ever wondered how open and closed coil springs differ in their design and function? The main difference lies in their coil manufacturing and spring material. Open coil springs have coils that are exposed at one or both ends, which allows for more flexibility and compression. Closed coil springs, on the other hand, feature coils that are fully enclosed or capped at the ends, providing a more controlled and uniform response. The spring material impacts their durability and stiffness, with steel alloys being common choices. Open coil springs are typically easier to manufacture and adjust, but may feel stiffer under certain conditions. Closed coil springs offer a smoother, more consistent feel, as their design limits coil movement during compression.

What Are the Main Design Features of Open Coil Systems?

Open coil systems feature a distinctive coil arrangement with widely spaced turns that allow for flexibility and controlled compression. The materials used and construction techniques also play a vital role in their performance and durability. Understanding these design features helps you choose the right spring for your specific application. Additionally, advancements in European cloud innovation contribute to improved manufacturing processes and material selection, enhancing the overall quality of open coil springs.

Coil Arrangement and Spacing

The arrangement and spacing of coils are key factors that define the main design features of open coil systems. Tighter coil spacing generally increases spring stiffness, making the spring feel firmer under load. Conversely, wider spacing offers more flexibility, resulting in a softer feel. Proper coil arrangement influences not only performance but also spring durability, as evenly spaced coils reduce stress concentrations that can lead to failure. When installing open coil springs, understanding these spacing nuances is essential for effective installation techniques, ensuring the spring maintains its intended feel over time. Consistent spacing helps prevent uneven wear and enhances longevity. By paying close attention to coil arrangement and spacing, you can optimize the spring’s performance while ensuring it remains durable under regular use.

Material and Construction

Material and construction define the core characteristics of open coil spring systems, directly affecting their performance and durability. The spring material plays a vital role; high-quality steel like stainless or alloy steel offers strength and resilience, while softer metals may wear faster. Manufacturing techniques also influence spring behavior—precision winding and heat treatment improve consistency and longevity. Open coil springs typically feature exposed coils made through specific processes that control tension and flexibility. Variations in wire thickness, coil diameter, and the way they’re manufactured determine how stiff or compliant the spring feels. By selecting appropriate materials and employing advanced manufacturing methods, designers can tailor open coil springs to meet specific performance needs, whether for cushioning, support, or durability.

How Are Closed Coil Springs Built and Structured?

Closed coil springs are carefully designed with specific coil arrangements to guarantee stability and strength. The materials and composition are chosen for durability and performance, often involving high-quality metals. Manufacturing processes like winding, heat treatment, and finishing shape the final structure to meet precise specifications.

Coil Arrangement Design

To understand how closed coil springs are built and structured, you need to know that they typically consist of a helical wire wound tightly into a compact, continuous loop. This arrangement helps distribute stress evenly across the spring, reducing the risk of spring fatigue over time. The tightly wound coils provide stability and help maintain consistent performance under load. The design also enhances corrosion resistance because the close contact between coils limits exposure to moisture and debris, which could accelerate deterioration. Proper coil arrangement ensures the spring maintains its shape and resilience, even after repeated compression. This structural integrity is essential for longevity and reliable performance, especially in applications where consistent tension and spring fatigue resistance are critical. Additionally, Free Floating design principles can be applied to improve spring stability and adaptability in various environments.

Materials and Composition

The strength and durability of closed coil springs primarily depend on the type of wire used and how it’s processed. High-quality alloy wires, such as steel or stainless steel, enhance spring longevity by resisting fatigue and corrosion. The composition of the material affects how well the spring maintains its properties over time, especially under repeated stress. Thicker wires generally result in stiffer springs but can increase manufacturing costs. The alloy’s treatment, like heat-treating or tempering, also plays an essential role in optimizing performance. While premium materials improve durability, they may raise manufacturing costs. Balancing material choice with design needs ensures your spring remains reliable and cost-effective, providing consistent performance throughout its lifespan. Additionally, understanding the materials and composition is crucial for customizing springs to suit specific applications and performance requirements.

Manufacturing Processes

Manufacturing closed coil springs involves a series of precise steps that shape and assemble the wire into its final form. First, the wire is carefully selected based on material properties and manufacturing tolerances. It’s then coiled around a mandrel to ensure consistent diameter and pitch. Heat treatment follows to optimize spring fatigue resistance, preventing premature failure. During production, strict quality controls monitor manufacturing tolerances to maintain uniformity. You might also see processes like shot peening, which enhances durability by inducing beneficial surface stresses. These steps help guarantee the spring’s resilience under repeated loads. Proper manufacturing minimizes variations that could lead to uneven stress distribution, reducing the risk of spring fatigue. This meticulous process results in a spring that feels predictable, reliable, and capable of withstanding repeated compression.

How Does Spring Construction Influence Stiffness?

Ever wonder how the way a coil spring is built affects its stiffness? It all comes down to spring material and coil geometry. The material’s properties, like elasticity and tensile strength, directly influence how much force the spring can resist. For example, steel alloys tend to be stiffer than plastics. Coil geometry also plays a vital role; tighter coils or smaller diameters increase stiffness because they resist deformation more. The number of coils, their thickness, and the overall shape affect how the spring distributes force. A well-designed construction balances these factors to achieve the desired stiffness. Understanding spring design helps you grasp why some springs feel firmer than others under the same load.

Why Are Open Coil Springs Usually Adjustable?

Open coil springs are usually adjustable because their design allows for easy modification of their length and tension. This adjustability is vital for fine-tuning spring compression to match specific vehicle needs or driving preferences. During coil manufacturing, the springs are created with several grooves or threaded sections that enable precise adjustments. This flexibility makes open coil springs ideal for applications requiring customizable tension. Additionally, their open design makes it simpler to modify tension without compromising structural integrity. Key reasons include:

- Ease of adjusting spring compression levels

- Simplified coil manufacturing process for customization

- Ability to fine-tune ride stiffness and handling

- Compatibility with various vehicle setups

- Understanding the design principles behind open coil springs enhances their effective use and modification.

How Do Coil Spring Types Affect Ride Comfort and Handling?

Your choice of coil spring type directly influences ride comfort and handling. Stiffer springs can improve stability during turns but may make the ride rougher, while softer springs offer a smoother experience but less control. Understanding these stiffness variations helps you find the right balance for your driving needs. For example, selecting a Youngster Choice inspired approach can help in making informed decisions based on your driving style and preferences.

Spring Stiffness Variations

Spring stiffness plays a essential role in determining how a vehicle responds to road conditions, directly impacting ride comfort and handling. Variations in spring stiffness come from factors like spring material and coil geometry. Heavier gauge spring material results in increased stiffness, providing better support but less comfort. Coil geometry, including coil diameter and number of turns, also influences stiffness—tighter coils tend to be stiffer. You’ll notice that open coil springs often feel softer due to their design, while closed coil springs feel stiffer. Understanding these differences helps you select the right spring for your driving needs. Spring material strength affects durability and stiffness, and the design choices in coil geometry—such as coil diameter and number of turns—also significantly impact overall spring performance.

Impact on Handling

The design differences between open and closed coil springs directly influence how your vehicle handles and rides over various surfaces. Open coil springs typically provide a softer feel, enhancing ride comfort and absorbing bumps better, but they may experience more spring fatigue over time, affecting handling precision. Closed coil springs tend to be stiffer, offering improved stability and sharper handling, especially during cornering. Proper installation tips include ensuring correct spring seating to prevent uneven wear and reduce spring fatigue, which can compromise handling. If you notice a change in ride quality or handling, it might be time to inspect your springs for signs of fatigue. Choosing the right coil spring type based on your driving needs can markedly improve your vehicle’s responsiveness and comfort.

Which Vehicle Types Usually Use Open or Closed Coil Springs?

Different vehicle types tend to favor either open or closed coil springs based on their specific performance needs. For example, sports cars often use closed coil springs to deliver a stiffer feel and improved handling, while trucks and SUVs typically opt for open coil springs for better load support and comfort. If you’re concerned about spring longevity, choosing the right spring type is vital, along with proper installation tips to prevent premature wear.

Choosing the right coil spring type enhances durability and ride quality based on your vehicle’s needs.

Consider these factors:

- Load capacity requirements

- Ride comfort preferences

- Handling performance

- Ease of replacement and maintenance

Understanding these differences helps you select the appropriate spring system for your vehicle, ensuring better durability and a smoother ride tailored to your driving style.

What Are the Pros and Cons of Open vs Closed Coil Springs?

Choosing between open and closed coil springs involves weighing their respective advantages and disadvantages. Open springs are easier to install and replace, making spring installation less complex. They also tend to offer a softer ride but may wear out faster with frequent use. Closed coil springs provide better durability and consistent performance, especially under heavy loads, but can feel stiffer. Here’s a quick comparison:

| Feature | Open Coil Springs | Closed Coil Springs | Common Use Cases |

|---|---|---|---|

| Spring installation | Easier & quicker | Slightly more complex | Light vehicles, quick fixes |

| Maintenance tips | Check for wear regularly | Inspect for cracks | Heavy-duty applications |

| Ride comfort | Softer, more flexible | Stiffer, more supportive | Performance vehicles |

| Durability | Less durable | More durable | Long-term use |

| Cost | Usually cheaper | Usually more expensive | Budget-conscious buyers |

Additionally, proper maintenance can extend the lifespan of both spring types, ensuring optimal performance over time.

How Do I Decide Which Coil Spring System Is Right for My Car?

To decide which coil spring system is right for your car, consider your driving needs and priorities. Think about how often you’ll drive on rough roads, your comfort preferences, and the vehicle’s load capacity. Open coil springs typically resist coil corrosion better, making them ideal if you face moisture or road salt frequently. Closed coil springs might be more prone to spring fatigue over time, affecting ride quality. Also, assess the potential for coil corrosion and how it could impact durability.

- How often you drive on rough terrains

- Your climate and exposure to moisture

- Long-term durability needs

- Your comfort versus handling preferences

Frequently Asked Questions

Can Open Coil Springs Be Replaced Easily?

Yes, open coil springs can be replaced easily if you guarantee spring compatibility. You’ll need to select the right spring type and size for your vehicle, then perform a spring replacement. It’s important to follow proper safety procedures and consider professional help if you’re unsure. Proper spring replacement maintains ride quality and prevents damage, so double-check compatibility to ensure a smooth, effective upgrade or repair.

Do Closed Coil Springs Last Longer Than Open Coil Springs?

Think of closed coil springs as guardians, weathering the storm longer than open coils. They typically last longer because their sealed design protects against spring corrosion, which can weaken open coil springs over time. This means your closed coil springs resist wear better, providing you with more reliable spring longevity. If durability matters, opting for closed coil springs helps your suspension stay resilient and perform smoothly through the years.

Are Open Coil Springs More Suitable for Performance Vehicles?

Yes, open coil springs are often more suitable for performance vehicles because they offer better spring compatibility and can be tuned for higher performance. You should consider vehicle compatibility to guarantee ideal handling and ride quality. Open coil springs typically provide more flexibility for customization, making them ideal if you’re looking for enhanced responsiveness and performance. Always check your vehicle’s specifications to select the right spring type for your needs.

How Does Spring Material Affect Stiffness and Durability?

You’ll find that spring material greatly impacts stiffness and durability; for example, steel alloys are 20% more resistant to spring fatigue than traditional materials. Stronger materials, like high-tensile steel, resist corrosion and fatigue longer, maintaining consistent performance. If you choose the right material, your springs will stay stiffer and last longer, even in harsh conditions. This balance guarantees your vehicle handles well and minimizes the need for frequent replacements.

What Maintenance Is Required for Different Coil Spring Types?

You should regularly inspect your coil springs for spring corrosion and follow proper installation procedures to guarantee longevity. For open coil systems, keep an eye out for rust or wear, and clean them as needed. Closed coil springs require less maintenance but still benefit from periodic checks. Always follow manufacturer guidelines for maintenance, and address issues promptly to maintain peak performance and prevent failure.

Conclusion

Choosing between open and closed coil springs depends on your driving needs. If you want a softer ride, open coils might be your best bet; for more stiffness and control, closed coils are ideal. Remember, “you get what you pay for,” so consider your vehicle type and driving style. By understanding their differences, you can pick the spring system that keeps you comfortable and safe on the road.