The biggest difference most people miss is how each foam reacts to heat and pressure. Memory foam molds to your body, responding slowly and trapping heat, which can cause overheating. Polyfoam, on the other hand, is more responsive, stays cooler, and offers quicker bounce. While durability and eco-impact vary, understanding these key contrasts helps you pick the right support. Continue exploring to uncover more about how these materials truly compare.

What Is Memory Foam? Characteristics and Composition

Memory foam is a specialized type of polyurethane foam designed to contour to your body’s shape and provide targeted support. Its unique memory foam properties include viscoelasticity, allowing it to slowly respond to heat and pressure, which helps it mold precisely to your curves. This responsiveness makes it ideal for pressure relief and comfort. Memory foam’s composition involves a dense, open-cell structure that absorbs energy and gradually returns to its original shape. Because of its adaptability, memory foam is widely used in mattresses, pillows, and cushioning, showcasing its versatility in polyfoam applications. Its ability to conform and support makes it popular for those seeking personalized comfort and pressure distribution, setting it apart from other foam types in both function and design. Additionally, understanding the odor characteristics of memory foam can help users select the right product for their preferences. The manufacturing process also influences the foam’s durability and safety, making it an important aspect to consider when choosing memory foam products. For example, the density and firmness levels can significantly impact comfort and longevity. Furthermore, variations in quality standards can affect the overall performance and safety of memory foam items. Moreover, the testing and certification processes ensure that memory foam meets safety and performance benchmarks.

What Is Polyfoam? Characteristics and Composition

Polyfoam is made from polyurethane, which gives it a versatile and lightweight structure. Its unique cellular design provides different levels of support and comfort, depending on the density. You’ll also find that polyfoam tends to be durable, but its lifespan varies based on quality and usage. Additionally, the use of performance cookies can help manufacturers analyze how different polyfoam types perform over time. The composition of polyfoam can be customized to meet specific comfort and support needs, making it a popular choice in various bedding and furniture applications. Its flexibility allows for tailoring specific formulations to enhance durability and responsiveness, further expanding its applications across the industry. The ability to modify density and other properties makes polyfoam adaptable to a wide range of products, with advancements in manufacturing techniques continually improving its performance and sustainability.

Material Composition Details

Polyfoam, a popular type of polyurethane foam, is made from a combination of petrochemical-based chemicals that create a versatile and lightweight material. Its foam density varies depending on the formulation, affecting durability and support. Higher foam density generally means a firmer, more supportive product, while lower density offers a softer feel. Chemical additives are often incorporated to enhance properties like fire resistance, odor control, and stability. These additives influence the foam’s flexibility and resilience, making it suitable for different applications. Additionally, manufacturing processes play a crucial role in determining the final characteristics of the foam, impacting its performance and safety standards. The chemical composition of polyfoam allows for customization, so manufacturers can adjust density and additives to meet specific needs. Overall, its material makeup provides a balance of affordability, durability, and comfort, which makes it a popular choice in furniture, mattresses, and insulation. The versatility of polyfoam also enables it to be tailored for various uses, further broadening its applications across industries.

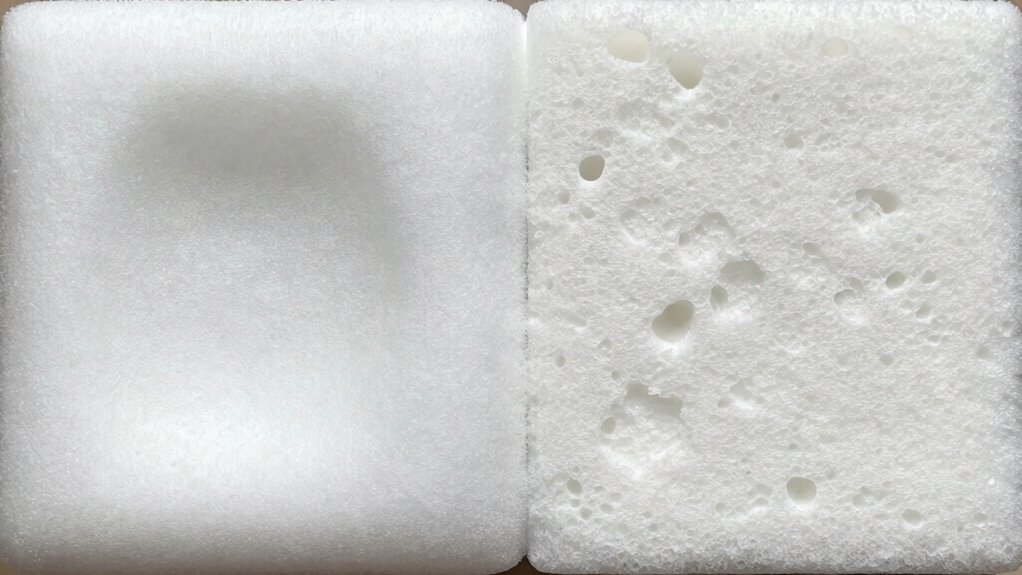

Unique Structural Features

Understanding the unique structural features of polyfoam helps you appreciate its versatility and performance. Polyfoam is characterized by its open-cell structure, which provides flexibility and quick responsiveness. Its cellular makeup allows for consistent support and cushioning, thanks to its inherent structural integrity. During the manufacturing process, polyfoam is created through the polymerization of foam-forming chemicals, resulting in a lightweight, porous material. This process guarantees that the foam maintains its shape and resilience over time. Unlike denser foams, polyfoam’s structure allows for easy customization in firmness and density, making it suitable for various applications. Additionally, the manufacturing process of polyfoam influences its durability and environmental footprint. The open-cell structure also contributes to its excellent breathability, which helps in moisture management and overall comfort. Overall, these structural features give polyfoam its distinct balance of support, comfort, and adaptability.

Durability and Lifespan

Because of its cellular structure and manufacturing process, polyfoam offers impressive durability and a long lifespan when used properly. Its foam density plays a vital role—higher density indicates stronger material less prone to material deterioration. You’ll find that polyfoam maintains its shape and support over time, especially when designed with quality standards. As polyfoam ages, it may experience some material deterioration, but this typically occurs slowly if the foam is of high quality. To maximize durability, avoid exposure to excessive moisture or heat. Additionally, the presence of high-quality manufacturing processes further enhances the longevity of polyfoam products. Proper foam maintenance can also extend its lifespan significantly, and understanding foam composition can help in selecting the best options for long-term use. Recognizing the water resistance of polyfoam can also be beneficial in environments where moisture exposure is unavoidable. Furthermore, material testing and adherence to industry standards can ensure the durability and safety of polyfoam products over time.

How Do Memory Foam and Polyfoam Respond to Pressure and Heat?

When you sit or lie on memory foam and polyfoam, you’ll notice they respond differently to pressure and heat. Memory foam molds closely to your body, becoming softer as it warms up, offering better support and comfort. Polyfoam, on the other hand, stays more firm and less responsive to temperature changes, affecting how it adapts to your movements. Additionally, the material’s response to pollutants can influence how well each type maintains air quality in your environment. Incorporating smart home ventilation systems can help mitigate any potential air quality concerns related to these materials. The material’s durability also plays a role in its long-term performance and safety. Proper air purifier maintenance and regular filter replacements are essential to ensure a healthy indoor environment when using these foams.

Response to Pressure and Heat

Memory foam responds to pressure and heat by softening and molding to your body’s contours, creating a personalized fit. This ability enhances pressure relief by evenly distributing weight and reducing pressure points. Additionally, heat retention allows the foam to respond more quickly to your body’s warmth, increasing comfort over time.

Consider these key points:

- Memory foam’s response improves pressure relief by conforming closely to your shape.

- Heat retention makes it more responsive as it warms, but can also cause overheating.

- Polyfoam reacts less to heat, providing more consistent support but less personalized pressure relief.

- The heat sensitivity of memory foam can influence its adaptability and long-term comfort.

Understanding these responses helps you choose the right material for your sleep needs.

Material’s Adaptability and Comfort

The way memory foam and polyfoam respond to pressure and heat directly impacts their adaptability and overall comfort. Memory foam molds closely to your body, offering excellent customization options that enhance support and pressure relief. Its material flexibility allows it to adapt quickly to your movements, providing a tailored feel. Polyfoam, on the other hand, tends to be more responsive and bouncier, but with less contouring. Its adaptability depends on density and formulation, which can be adjusted for different comfort levels. While memory foam excels in conforming to your shape, polyfoam offers more immediate responsiveness. Both materials’ ability to respond to heat and pressure influences your overall sleep experience, making material flexibility a key factor in choosing the right foam for your comfort needs.

How Long Do Memory Foam and Polyfoam Last? Durability Compared

While both memory foam and polyfoam are popular choices for mattresses and cushions, their durability can vary considerably. Your choice impacts how long your investment lasts, influenced by key durability factors. Typically, memory foam has a longer lifespan, often lasting 7-10 years, while polyfoam may last 5-7 years. Here are some durability factors to weigh:

Memory foam typically lasts longer (7-10 years) than polyfoam (5-7 years), depending on quality and use.

- Material density—higher density usually means better longevity.

- Quality of raw materials—premium materials resist wear better.

- Usage frequency—more frequent use accelerates deterioration.

- Maintenance—regular upkeep can extend lifespan significantly.

Understanding these aspects helps you compare lifespan effectively, ensuring you select the right foam based on durability factors. This lifespan comparison clarifies which foam type suits your long-term needs best.

Do Memory Foam and Polyfoam Breath Well? Temperature and Airflow

Durability factors influence how long foam retains its supportive qualities, but breathability substantially affects comfort and temperature regulation. When it comes to breathability concerns, memory foam often struggles due to its dense structure, trapping heat and limiting airflow efficiency. This can lead to overheating and discomfort, especially during warmer nights. Polyfoam, on the other hand, generally offers better airflow due to its more open-cell design, allowing heat to dissipate more effectively. If you tend to sleep hot, airflow efficiency becomes a vital factor in choosing the right foam. While memory foam molds closely to your body, it can hinder breathability. Polyfoam’s open structure promotes better air circulation, helping you stay cooler and more comfortable throughout the night.

Are Memory Foam and Polyfoam Eco-Friendly? Off-Gassing and Impact

Memory foam and polyfoam differ substantially in their environmental impact, especially when it comes to off-gassing and overall eco-friendliness. Memory foam often contains chemicals that release volatile organic compounds (VOCs), leading to off-gassing that can affect indoor air quality. Polyfoam generally has a lower VOC emission but still impacts the environment. Considering recycling options is vital; memory foam is harder to recycle due to chemical composition, whereas polyfoam can sometimes be repurposed. To assess eco-friendliness, look at these factors:

- VOC emissions during and after manufacturing

- Durability and lifespan of the foam

- Availability of recycling options

- Overall environmental impact of production processes

Being aware of these aspects helps you make a more sustainable choice.

What Are the Costs of Memory Foam vs Polyfoam? Is It Worth It?

Choosing between memory foam and polyfoam often comes down to cost and value. In a pricing comparison, memory foam generally costs more upfront due to its manufacturing process and material quality. Polyfoam, being cheaper to produce, offers an affordable option but may sacrifice longevity and comfort. When considering the environmental impact, memory foam tends to have a higher footprint because of its petroleum-based components and off-gassing concerns. Polyfoam’s lower cost can sometimes mean less sustainable production practices. Ultimately, if you prioritize durability and comfort, investing in memory foam might be worth the higher price. However, if budget and environmental considerations are your top priorities, polyfoam provides a cost-effective alternative. Weighing these factors helps determine if the extra expense is justified for your needs.

Where Are Memory Foam and Polyfoam Used? Best for Different Sleepers

Memory foam and polyfoam each suit different sleep needs, making them ideal for specific types of sleepers. If you’re a side sleeper, memory foam’s contouring support relieves pressure points and keeps your spine aligned. For back sleepers, polyfoam offers firmer support that maintains proper posture. If allergy concerns are a priority, hypoallergenic memory foam can reduce dust mites and allergens better than polyfoam. Conversely, stomach sleepers often prefer the more resilient feel of polyfoam, which prevents excessive sinking. Consider these factors:

Memory foam contours for side sleepers; polyfoam supports back and stomach positions.

- Sleep position (side, back, stomach)

- Pressure relief needs

- Support and firmness preferences

- Allergy sensitivities

Choosing the right material depends on your unique sleep style and health considerations, ensuring better rest tailored to your needs.

Frequently Asked Questions

How Do Memory Foam and Polyfoam Compare in Motion Transfer?

Memory foam excels at reducing motion transfer, providing better motion isolation, so you won’t feel disturbance transfer from your partner or movement on the bed. Polyfoam, on the other hand, typically allows more movement, meaning disturbance transfer is more noticeable. If you’re sensitive to motion, memory foam offers a quieter, more stable sleep experience. Polyfoam may be less effective at minimizing motion transfer, potentially leading to more disturbance during sleep.

Can Memory Foam or Polyfoam Cause Allergies or Skin Sensitivities?

About 10-15% of people report allergy triggers and skin sensitivities from memory foam or polyfoam. You might experience irritation if you’re sensitive to chemicals used in manufacturing or materials like latex or synthetic fibers. To avoid issues, choose hypoallergenic, organic options, and guarantee proper ventilation. Knowing your sensitivities helps you select the right foam type, reducing the risk of allergic reactions and skin irritations.

Are There Health Risks Associated With Off-Gassing From These Foams?

Off-gassing from memory foam and polyfoam can pose health risks because of chemical emissions, which may affect indoor air quality. You might notice odors or experience respiratory irritation, especially in poorly ventilated spaces. To minimize risks, look for foams labeled low-VOC or CertiPUR-US certified. Ensuring good ventilation during and after setup can also help reduce chemical exposure, keeping your indoor environment safer and healthier.

What Are the Environmental Impacts of Manufacturing Memory Foam Versus Polyfoam?

You’ll find that manufacturing memory foam tends to be more environmentally taxing than polyfoam, due to its higher chemical demand and energy use. However, choosing sustainable materials and recycling options can lessen this impact. While polyfoam’s production is less intensive, it still contributes to pollution. By being mindful of these factors, you can make more responsible choices, supporting sustainable solutions and reducing environmental footprints in foam manufacturing.

How Does the Weight of These Materials Affect Shipping and Handling?

The shipping weight of memory foam is generally higher than polyfoam, making handling considerations more challenging. Heavier materials require more effort and potentially higher costs for transportation and storage. When you handle these materials, keep in mind that increased weight can impact logistics, requiring sturdier packaging and careful lifting techniques. Choosing lighter polyfoam can ease shipping weight concerns, but consider how weight affects overall handling and delivery expenses.

Conclusion

Ultimately, choosing between memory foam and polyfoam is like selecting the perfect suit—you’ll want one that fits your needs best. Both have their quirks, but understanding their differences helps you make a smarter decision. Remember, the right foam can be your sleep’s best friend, wrapping you in comfort or providing sturdy support. So, weigh your options carefully—after all, a good night’s sleep is the foundation of a great day.