Barrier socks and inner covers are fiberglass-based components that protect your fiber optic cables from environmental damage, dust, and mechanical stress. Properly installed, they improve safety, prevent fiber exposure, and extend the system’s lifespan. Many overlook these details, risking damage and system failure. Understanding how these components work and ensuring correct installation can make a big difference. Keep going, and you’ll discover essential tips to enhance their effectiveness and longevity.

Key Takeaways

- Barrier socks and inner covers use fiberglass reinforcement combined with specialized coatings for durability and environmental resistance.

- They contain stray fibers, reducing health hazards and preventing fiber exposure during installation or maintenance.

- Proper installation ensures effective sealing against moisture, dust, and mechanical stress, extending fiber optic system lifespan.

- Material compatibility and correct handling prevent damage, peeling, or gaps that could compromise protection.

- Regular inspection and maintenance are essential to detect wear, tears, or gaps that may reduce barrier effectiveness.

What Are Barrier Socks and Inner Covers?

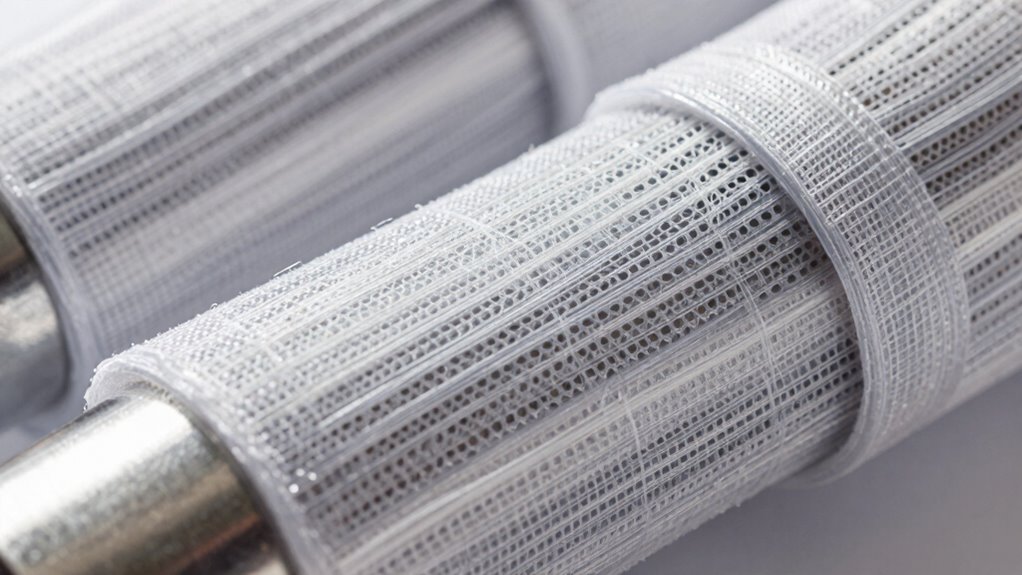

Ever wondered what barrier socks and inner covers are? These are specialized components used in fiber optic installations to protect delicate connections. Barrier socks are small sleeves made from durable materials that slip over fiber optic cables, preventing damage during installation or maintenance. Inner covers serve as moisture barriers, sealing connectors and joints from humidity, dust, and other environmental factors. They help maintain signal integrity by preventing moisture ingress that could cause corrosion or signal loss. Both barrier socks and inner covers are essential in safeguarding fiber optic systems, especially in challenging environments. By adding these protective layers, you ensure your fiber optic connections stay clean, dry, and functional for longer periods, reducing maintenance needs and boosting overall reliability. Proper application of protective coverings can significantly extend the lifespan of fiber optic components and ensure consistent performance.

Why Do Barrier Socks and Inner Covers Matter?

Barrier socks and inner covers play an essential role in preserving the integrity of fiber optic connections. They protect delicate fibers from environmental damage, dust, and mechanical stress. Proper use guarantees coating compatibility, preventing issues like coating degradation or incompatibility that can compromise performance. Color coding helps you quickly identify fiber types, reducing installation errors and maintenance mishaps. Without these components, fibers are vulnerable to contamination and misidentification. They also help maintain proper bend radius and prevent fiber movement, which reduces signal loss. Additionally, understanding the evolution of the English language highlights how language adaptations can influence technical terminology and communication in fiber optics. By safeguarding connections, barrier socks and inner covers extend the lifespan of your fiber optic system.

- Protect against environmental contaminants

- Ensure coating compatibility and durability

- Facilitate quick fiber identification with color coding

- Maintain proper bend radius and minimize stress

- Reduce risk of signal loss and damage

What Materials Are Used in These Fiberglass Components?

Fiberglass components like barrier socks and inner covers are primarily made from reinforced fiberglass fabrics combined with specialized coatings. These materials guarantee durability and chemical resistance, critical for their protective roles. The fiberglass reinforcement provides strength, while material compatibility guarantees they can withstand specific environmental conditions without degrading. The coatings, often resin-based, enhance corrosion resistance and flexibility. Additionally, understanding material compatibility is essential for ensuring the longevity of these components in various applications.

How Do Barrier Socks and Inner Covers Improve Safety and Performance?

Barrier socks and inner covers boost safety by reducing the risk of fiberglass splinters and exposure. They also enhance performance by making materials more durable and resistant to wear. Together, these features help you work more confidently and efficiently. Proper maintenance of tools and protective features can also prolong their lifespan and effectiveness air purifier maintenance.

Enhanced Safety Measures

By incorporating barrier socks and inner covers, you markedly reduce the risk of injuries caused by fiberglass splinters and fibers. These protective layers contain stray fibers, preventing them from becoming airborne or penetrating skin. This containment is especially important in maintaining a safe working environment and ensuring compliance with health standards. These safety measures enhance safety during installation and maintenance, minimizing health hazards. Additionally, barrier socks help maintain fiberglass aesthetics by keeping fibers contained, preserving a clean appearance. They also support component branding by ensuring the product looks professional and well-finished. Using inner covers further ensures fibers stay within designated areas, reducing cleanup time and potential exposure. Overall, these safety measures promote a safer work environment, protect your team, and uphold the integrity of your fiberglass installations. They’re simple yet essential tools for improving safety and performance.

Improved Material Durability

Using barrier socks and inner covers directly enhances the durability of fiberglass components by protecting them from physical damage and environmental stressors. These protective layers help extend material longevity by shielding against abrasions, impacts, and chemical exposure that can cause deterioration. By improving wear resistance, they reduce the likelihood of cracks, chips, or surface degradation over time. This protection ensures that fiberglass components maintain their structural integrity longer, lowering maintenance costs and minimizing downtime. Additionally, barrier socks and inner covers act as a buffer against moisture and UV rays, which can weaken fiberglass. As a result, your equipment performs more reliably and lasts longer, offering better safety margins and consistent performance in demanding conditions.

What Are the Key Factors for Proper Installation?

To guarantee your barrier socks and inner covers are installed correctly, you need to focus on surface preparation, handling materials properly, and applying them accurately. Skipping steps or rushing can compromise their effectiveness and safety. Paying close attention to these key factors helps you achieve a secure and reliable installation. Additionally, understanding how drone insights can inform your installation process ensures you maximize safety and efficiency.

Surface Preparation Essentials

Proper surface preparation is essential to guarantee a secure and durable installation of barrier socks and inner covers. Ensuring the surface is clean, dry, and free of surface contamination is critical for optimal coating adhesion. Any dirt, oil, or debris can compromise the bond, leading to premature failure. You should thoroughly inspect the surface, removing any dust or residues that may hinder adhesion. Proper surface preparation also involves roughening the surface if needed, to create a better grip for the fiberglass materials. This process helps prevent issues like peeling or bubbling over time. Remember, neglecting these steps can result in reduced lifespan and performance of your barrier system. Focus on these key factors to ensure a successful, long-lasting installation. Incorporating surface contamination identification techniques can help you detect and address hidden issues before application.

Correct Material Handling

Handling barrier socks and inner covers correctly starts with careful attention to the materials themselves. Guarantee material compatibility by verifying that the fiberglass components suit your specific project requirements. Proper handling minimizes damage and maintains their protective properties. Be mindful of the environmental impact; avoid unnecessary waste by measuring accurately and storing materials properly. Use clean, dry tools to prevent contamination that could compromise the barrier’s integrity. Always follow manufacturer instructions regarding storage and handling to prevent fiber breakage or deformation. Additionally, consider the environment in which you’re working—extreme temperatures or humidity can affect material performance. Recognizing the importance of visual and auditory cues can further enhance handling precision and safety. By respecting these factors, you help ensure the barrier socks and inner covers perform effectively, last longer, and contribute to a safer, more sustainable installation process.

Proper Application Techniques

Ensuring the barrier socks and inner covers are installed correctly hinges on paying attention to several key factors. Proper application not only enhances clothing comfort but also maintains aesthetic appeal. To do this effectively, focus on:

- Ensuring a snug, even fit without wrinkles or gaps

- Cleaning surfaces thoroughly before installation

- Using compatible adhesives to prevent peeling or bubbling

- Handling materials carefully to avoid tears or deformities

- Following manufacturer instructions precisely for ideal performance

- Considering the material properties of the fiberglass covers to ensure compatibility and durability

Attention to detail during installation guarantees that fiberglass remains contained, reducing irritation and improving overall appearance. When applied properly, these covers stay secure, look neat, and don’t compromise clothing comfort. Correct techniques make all the difference in ensuring the barrier functions effectively and looks professional.

What Problems Can Happen If These Components Are Overlooked or Installed Wrongly?

When barrier socks or inner covers are overlooked or installed incorrectly, it can lead to serious issues like leaks, contamination, and equipment failure. Improper installation may compromise fire resistance and aesthetic considerations, making systems more vulnerable and less appealing. These mistakes can cause fiberglass fibers to become exposed, risking health hazards and reducing component durability. Additionally, poor installation can result in uneven coverage, leading to structural weaknesses and increased maintenance.

| Problem | Consequence |

|---|---|

| Leaks | Water or chemical intrusion |

| Contamination | Compromised product quality |

| Fire resistance issues | Increased fire risk |

Ignoring proper installation can turn a simple component into a critical failure point, affecting safety, appearance, and performance.

How Can You Inspect and Maintain Barrier Socks and Inner Covers?

Regular inspections are essential to guarantee barrier socks and inner covers are properly installed and functioning effectively. Use an inspection checklist to identify tears, gaps, or signs of wear. Regularly clean and inspect for fiberglass fraying or damage that could compromise the barrier. Follow maintenance routines like replacing worn components promptly and verifying secure attachments. Pay attention to these key points:

- Checking for tears, holes, or fraying

- Ensuring proper fit and secure attachment

- Cleaning to prevent buildup of debris

- Monitoring for signs of deterioration

- Replacing damaged or worn parts immediately

Additionally, understanding the performance ratings of filtration components can help determine when maintenance is necessary to maintain optimal airflow and safety.

Frequently Asked Questions

Are Barrier Socks Suitable for All Types of Fiberglass Applications?

Barrier socks are generally suitable for many fiberglass applications, but you should consider material compatibility and installation challenges. They work well with most resin systems, yet some materials may cause compatibility issues, leading to poor adhesion or chemical reactions. During installation, make sure the socks fit properly and are secured correctly to avoid gaps or movement. Always check your specific project’s requirements and material compatibility before choosing barrier socks for fiberglass work.

How Long Do Fiberglass Barrier Socks and Inner Covers Typically Last?

You can expect fiberglass barrier socks and inner covers to last around 3 to 5 years, depending on installation longevity and material durability. Proper installation and regular maintenance extend their lifespan, while exposure to harsh conditions may shorten it. Choosing high-quality materials and ensuring correct placement help maximize their durability, ensuring they effectively protect your fiberglass surfaces over time.

Can Barrier Socks Be Customized for Specific Equipment Sizes?

Yes, barrier socks can be customized for specific equipment sizes. You have design flexibility to tailor the dimensions to fit your equipment precisely. This guarantees a snug, secure fit, which enhances safety and effectiveness. Custom sizing allows you to address unique equipment shapes and sizes, reducing wear and tear. By working with manufacturers offering customization options, you can guarantee your barrier socks meet your exact needs without compromising performance or durability.

What Are the Environmental Impacts of Using These Fiberglass Components?

You might worry about fiberglass components harming the environment, but recycling challenges and pollution concerns are minimal if managed properly. These materials are durable, reducing waste, and advancements in recycling techniques help lessen their ecological footprint. By choosing high-quality fiberglass products, you help minimize disposal issues, and proper handling prevents pollution. So, with responsible use, you can enjoy their benefits while supporting environmental sustainability.

Are There Industry Standards Governing the Use of Barrier Socks and Covers?

Yes, industry regulations and safety standards govern the use of barrier socks and covers. You should guarantee that these components meet specific safety criteria to prevent fiberglass exposure and maintain product integrity. Regulations often require testing for durability, fire resistance, and environmental safety. By adhering to these standards, you protect workers and end-users while ensuring compliance with industry guidelines, ultimately promoting safer and more reliable fiberglass applications.

Conclusion

Don’t overlook barrier socks and inner covers—they’re vital for safety and performance. Even if they seem minor, proper installation and maintenance guarantee your fiberglass components stay protected and efficient. You might think it’s extra work, but skipping these details could lead to costly repairs or safety hazards down the line. Stay vigilant, inspect regularly, and you’ll keep your equipment running smoothly—because when it comes to fiberglass, attention to detail makes all the difference.