To avoid the slat spacing mistake in a hybrid setup, you need to carefully measure and plan every step. Using precise tools like laser levels and spacer blocks helps guarantee even spacing and proper alignment. Skipping these steps can lead to uneven surfaces, rework, and added costs. Paying close attention to measurement accuracy during installation prevents mistakes early on. Continue exploring so you can master the key techniques to get perfect slat spacing every time.

Key Takeaways

- Measure and verify slat spacing carefully to ensure uniform gaps and prevent misalignments.

- Use precise tools like laser levels and spacer blocks for consistent and accurate installation.

- Double-check measurements multiple times before securing slats to avoid costly mistakes.

- Document spacing and setup procedures for quality control and future adjustments.

- Regularly inspect during installation to identify and correct errors promptly, minimizing rework and delays.

What Is the Hybrid Setup Rule, and Why Does It Matter?

Have you ever wondered how combining different work or gaming setups can optimize performance? The hybrid setup rule centers on proper installation techniques and material selection to guarantee stability and efficiency. This rule emphasizes that choosing the right materials—like sturdy slats or adaptable mounting options—can considerably impact your setup’s durability. Proper material selection and installation techniques are vital; precise measurements and secure fastening prevent issues down the line. Ignoring these factors leads to uneven performance or potential damage. The rule isn’t just about following steps but understanding how each component interacts within your setup. When you prioritize proper material selection and meticulous installation, you create a reliable, high-performing environment tailored to your needs. That’s why adhering to the hybrid setup rule matters for long-term success. Proper European cloud innovation and adherence to sustainable practices further enhance the resilience and efficiency of your overall system.

Why Is Proper Slat Spacing Crucial for Hybrid Installations?

Proper slat spacing is essential for hybrid installations because it directly affects support, stability, and airflow. When spacing is correct, slat reinforcement ensures the structure can handle weight and resist shifting. Proper gaps also promote ideal airflow, improving ventilation and energy efficiency. If slats are too close, it can hinder airflow and cause aesthetic issues, making the setup look cluttered. Conversely, too wide a gap compromises support, risking sagging or damage over time. Aesthetic considerations are crucial; well-spaced slats create a clean, uniform appearance that enhances your setup’s visual appeal. Additionally, appropriate slat spacing can prevent potential structural issues and prolong the lifespan of your installation. Ensuring proper slat spacing balances structural integrity with visual harmony, preventing potential issues that could arise from poor support or unattractive design. Proper airflow management is essential for maintaining a comfortable environment and maximizing system efficiency. Paying attention to slat spacing guidelines can significantly improve the overall performance and longevity of your hybrid setup. To achieve optimal results, always consider installation best practices to match your specific setup requirements.

What Common Mistakes Lead to Slat Spacing Errors?

One common mistake that leads to slat spacing errors is neglecting accurate measurements during installation. If you don’t double-check measurements, your panel alignment can become skewed, causing uneven gaps. Rushing through measurement tasks often results in inconsistent spacing, especially when working with different material selections that may have slight variations. Choosing the wrong materials without considering their thickness and expansion properties can also lead to spacing issues later. Failing to account for these factors creates gaps that are either too tight or too wide, compromising the overall look and function. Precision in measurement and careful consideration of material selection are essential to avoid these mistakes. Proper planning ensures consistent slat spacing and a professional finish.

How Does Improper Spacing Cost You Time and Money?

When your slat spacing isn’t right, you’ll spend more time on installation, slowing down your project. Improper spacing also leads to wasted materials, driving up costs unnecessarily. Overlooking these details can quickly eat into your budget and delay your completion date. Using the correct fabric decorating markers can help ensure your project stays on track and looks professional. Ensuring proper auditory processing during planning can also contribute to smoother project execution. Additionally, understanding global chaos, such as major outages, can help you prepare contingency plans to avoid unexpected delays. Paying attention to load‑planning tools can optimize your setup and prevent costly adjustments later. Being aware of zodiac traits and their influence on your decision-making can also help you stay focused and avoid common pitfalls that lead to setbacks.

Increased Installation Time

Improper spacing during installation can considerably extend the time it takes to complete your setup. When your slat design isn’t properly aligned, you’ll need to spend extra effort correcting mistakes, which slows down the process. Poorly executed installation techniques often lead to rework, as you may have to remove and reposition slats to achieve proper spacing. This not only causes delays but also increases material waste and labor costs. This extra effort can be avoided by understanding the importance of installation best practices and ensuring accurate measurements from the start. Proper planning and precise measurement techniques help prevent errors before they happen. Additionally, familiarity with installation guidelines ensures that all components fit correctly on the first try, reducing the need for adjustments. Paying close attention to slat spacing during initial setup can significantly streamline the process. By adhering to manufacturing standards and following recommended installation techniques, you can complete your setup more efficiently, avoiding unnecessary setbacks that cost both time and effort.

Elevated Material Costs

Incorrect spacing during installation often leads to material waste, driving up costs and extending your project timeline. When slats aren’t properly spaced, you may need to order extra materials to compensate for mistakes, reducing material efficiency. Poor spacing also hampers design optimization, making it harder to achieve a sleek, cohesive look without unnecessary cuts or adjustments. This inefficiency results in higher material expenses and increased labor costs. Overusing or underusing materials due to improper spacing means you’re not maximizing the value of your investment. By paying attention to slat spacing, you can minimize waste, streamline your workflow, and keep your project within budget. Proper spacing isn’t just about aesthetics—it’s a smart way to control material costs and ensure your project runs smoothly.

How Can You Measure and Calculate Slat Spacing Correctly?

To measure and calculate slat spacing accurately, you need to start by using a precise ruler or tape measure to determine the distance between the edges of adjacent slats. Focus on measurement techniques that guarantee consistency, such as measuring at multiple points along each slat to account for irregularities. When calculating, apply the correct calculation formulas to determine the average spacing, factoring in any variation observed. Here are key steps:

Use precise measurements at multiple points to accurately determine slat spacing.

- Measure the gap at several locations for accuracy.

- Record all measurements carefully.

- Use average values and formulas to determine precise spacing.

- Incorporating measurement techniques that ensure consistency can significantly improve the accuracy of your calculations. Additionally, verifying the uniformity of slats helps avoid errors caused by uneven surfaces or manufacturing inconsistencies. Recognizing potential manufacturing tolerances is essential because slight variations in manufacturing can impact overall measurements. It is also helpful to consider the natural variability that may affect the measurement process, especially when working with reclaimed or irregular materials. Employing proper calibration of measuring tools can further enhance measurement reliability.

What Tools Do You Need for Accurate Slat Spacing?

To achieve accurate slat spacing, you need the right measurement tools. A precise tape measure or a digital caliper can help guarantee consistent alignment. Having these essential tools makes it easier to maintain proper spacing throughout your project. Additionally, understanding smart appliance integration can further optimize your setup for efficiency and precision. Being aware of measurement accuracy principles ensures your spacing remains consistent and professional-looking.

Tools for Precise Measurement

Achieving accurate slat spacing relies on using the right tools to measure precisely. Proper measuring techniques ensure consistent results and help avoid costly mistakes. To start, invest in a high-quality tape measure or ruler with fine gradations, allowing for precise readings. Next, a digital caliper offers exceptional accuracy for measuring small distances between slats, especially when calibration is maintained regularly. Finally, a laser distance meter can quickly provide exact measurements over longer spans, saving time and increasing accuracy. Always verify your tools’ calibration before use to prevent errors. These tools enable you to maintain consistency in spacing, ensuring your slats are evenly aligned and properly installed. Accurate measurement is the foundation of a flawless setup.

Essential Spacing Tools List

Having the right tools on hand makes measuring and maintaining consistent slat spacing much easier. A tape measure is essential for accurate distance checks, especially when aligning slats with framing guidelines. A carpenter’s square ensures your slats stay perfectly perpendicular, preventing misalignment that affects solar panel installation. A level helps maintain flat, even spacing across the entire setup. For precise measurements, consider using a spacer block or a dedicated slat spacing gauge—these tools help achieve uniform gaps quickly. Marking tools like a pencil or chalk are useful for temporary guides. When working near solar panels, double-check measurements to avoid damaging sensitive components. With these tools, your slat spacing becomes more accurate and dependable, ensuring ideal support and alignment for your solar panel system.

Ensuring Consistent Alignment

Ensuring consistent alignment requires selecting the right tools to achieve precise and uniform slat spacing. Accurate measurement is key to maintaining balance, especially when coordinating decorative accents and color schemes. Use these tools to enhance your setup:

- Laser Level – Ensures straight, even lines for perfect alignment across the entire installation.

- Measuring Tape – Confirms consistent spacing between slats, supporting cohesive color coordination and decorative accents.

- Spacing Blocks or Shims – Provides uniform gaps, making it easier to maintain decorative consistency and overall visual harmony.

Using these tools helps you avoid mistakes that can disrupt symmetry, guaranteeing your slats are perfectly aligned and your design looks polished and intentional.

How Do You Install Slats for the Best Results?

To install slats for the best results, start by measuring your space carefully and choosing the right type of slats for your setup. During slat installation, pay close attention to your spacing techniques to ensure even gaps and a uniform look. Use a ruler or measuring tape to mark consistent intervals along the frame, keeping the spacing tight enough for stability but not so tight that it restricts airflow. It’s helpful to lay out the slats in advance, adjusting until you’re satisfied with the fit. Secure each slat firmly, maintaining consistent spacing throughout. Proper spacing not only enhances visual appeal but also prevents warping or sagging over time. Taking your time with accurate measurements and spacing will give you a professional, durable result.

How Can You Fix and Troubleshoot Spacing Mistakes?

When you notice spacing mistakes, the first step is to measure and adjust to guarantee everything lines up correctly. Using the right spacing tools makes this process easier and more accurate. By following these steps, you can fix issues efficiently and keep your setup looking professional.

Measure and Adjust Properly

If you notice spacing mistakes in your hybrid setup, the key is to measure carefully and make precise adjustments. Start by applying proper measurement techniques, ensuring your tools are accurate and your readings consistent. Use a level or a straightedge to verify slat alignment, and double-check your measurements at multiple points for accuracy. To fix issues effectively, follow installation best practices, such as maintaining consistent spacing during installation and avoiding forceful adjustments that could damage the materials. Here are essential steps to contemplate:

- Measure multiple points to confirm uniformity.

- Use precise tools for consistent readings.

- Adjust slats gradually, checking alignment after each tweak.

This approach helps you troubleshoot spacing mistakes efficiently and achieve a professional finish.

Use Correct Spacing Tools

Are you unsure which tools are best for fixing spacing mistakes in your hybrid setup? Using the right spacing tools simplifies correcting errors and guarantees consistent slat gaps. Start by selecting precise measurement techniques—calipers, rulers, or tape measures—that give accurate readings. These measurement tools help you identify uneven spacing quickly. When troubleshooting spacing mistakes, rely on proper spacing tools like spacer blocks or specialized jigs designed for your specific setup. These tools help maintain uniform gaps during adjustments. Always double-check your measurements before making any changes. By choosing the correct measurement techniques and spacing tools, you can fix spacing errors efficiently, preventing future issues and achieving a professional, clean look in your hybrid setup.

What Are Simple Tips to Prevent Spacing Errors Next Time?

Want to avoid spacing errors in your documents? Ensuring spacing consistency and measurement accuracy is key. Here are three simple tips:

Maintaining consistent spacing and accurate measurements keeps your documents error-free and professional.

- Double-check measurements before marking or cutting to prevent errors early on.

- Use a reliable measuring tool, like a ruler or tape, to maintain consistency throughout.

- Regularly verify spacing during the process, adjusting as needed to keep everything aligned.

What Key Takeaways Ensure a Successful Hybrid Setup?

To guarantee your hybrid setup runs smoothly, focus on key practices that promote coordination and consistency. Follow installation best practices by carefully planning each step, double-checking measurements, and assure proper alignment. Material selection is crucial; choose high-quality, compatible materials that suit your environment and design goals. Properly training your team on installation procedures minimizes errors and maintains uniformity across the setup. Regular inspections during installation help identify issues early, preventing costly mistakes. Document your process to create a reliable reference for future adjustments. Prioritize clear communication among team members to ensure everyone understands their roles. By adhering to these key takeaways—solid installation practices and thoughtful material choices—you set your hybrid setup up for long-term success and durability.

Frequently Asked Questions

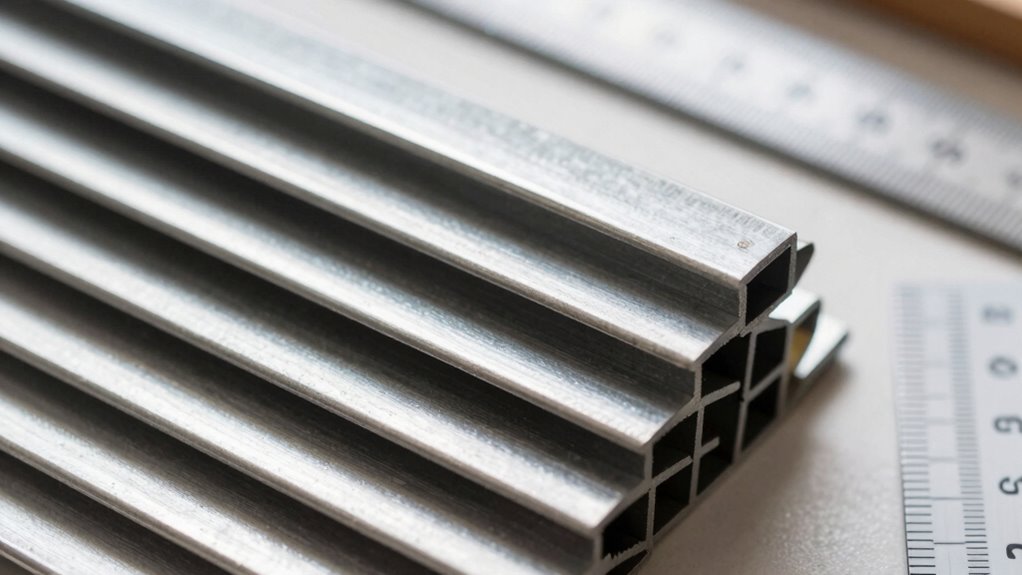

How Does Slat Material Affect Spacing Requirements?

You need to consider the slat material because it directly impacts spacing optimization. Heavier or thicker materials, like metal or dense wood, may require larger gaps to prevent warping or sagging, while lighter materials allow for tighter spacing. Your choice of material considerations influences how closely you can space the slats without compromising stability or functionality, ensuring your setup remains durable and visually appealing.

Can Uneven Slat Spacing Cause Safety Issues?

Yes, uneven slat spacing can cause safety hazards and reduce equipment longevity. When spacing isn’t consistent, it increases the risk of accidents like slips or falls, especially if users trip over uneven surfaces. Additionally, uneven spacing puts extra stress on the slats and supporting structures, leading to faster wear and potential damage. Ensuring proper, uniform spacing helps maintain safety and extends the lifespan of your equipment.

What Are the Best Practices for Maintaining Consistent Spacing?

To maintain consistent slat spacing, you should plan your design carefully, considering both safety and aesthetic considerations. Use precise measurements and tools like spacers to guarantee even gaps throughout. Regularly check the spacing during installation and after completion, adjusting as needed. This approach not only enhances safety but also provides design flexibility, giving your project a polished, professional look with uniform appearance and ideal functionality.

How Often Should Slat Spacing Be Inspected and Adjusted?

You should inspect and adjust slat spacing weekly to prevent safety issues and guarantee proper function. Regular checks help you spot gaps or misalignments in the slat material early, reducing the risk of accidents. Keep an eye on the spacing, especially after maintenance or high usage, and adjust as needed. Consistent inspection maintains safety standards and prolongs the lifespan of your setup.

Are There Industry Standards for Slat Spacing in Hybrid Setups?

You should follow industry standards for slat spacing in hybrid setups, which typically recommend gaps of 1/4 inch to 1/2 inch, ensuring safety and efficiency. Did you know that improper slat spacing can cause safety issues, leading to accidents or equipment damage? Your slat material, whether metal or plastic, influences these standards. Regular inspections help maintain proper spacing, preventing hazards and ensuring smooth operation.

Conclusion

Think of your hybrid setup as a finely tuned orchestra; every slat must be perfectly spaced to create harmony. When you pay close attention to spacing, you avoid costly mistakes and keep your project running smoothly. By measuring carefully and installing thoughtfully, you guarantee everything plays in tune. Remember, precision isn’t just a detail—it’s the conductor that keeps your setup’s performance flawless and your effort truly worth the symphony.